Intshayelelo kwi-O-rings

Yintoni i-O-ring?

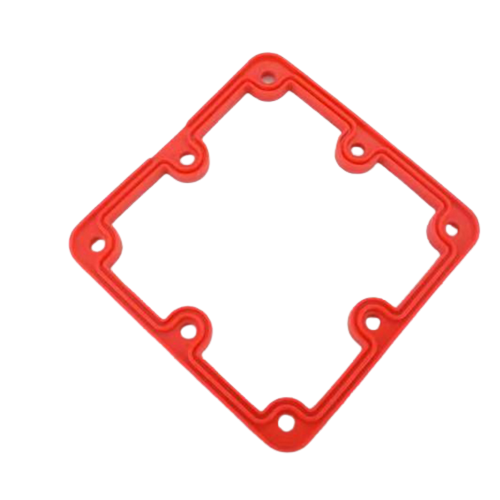

I-O-ring licandelo lokutywina elijikelezayo elenziwe ngezinto ze-elastomer, ngokuqhelekileyo irabha okanye i-silicone.Uyilo lwayo lufana ne-donut-shaped loop kunye ne-cross-section ejikelezayo.Umsebenzi ophambili we-O-ring kukudala itywina phakathi kweendawo ezimbini zokukhwelana, ukuthintela ukuhamba kwamanzi okanye iigesi.Ifezekisa oku ngokuxinzelelwa phakathi kwemigangatho, ukudala umqobo oqinileyo kunye nothembekileyo.

Iindidi ze-O-amakhonkco

Xa ukhetha i-O-ring yesicelo esithile, izinto ezininzi kufuneka ziqwalaselwe.Masiphonononge imiba ephambili ekufuneka sigxile kuyo:

3.1.Ukukhethwa kwezinto

Ukukhethwa kwezinto ze-O-ring kuxhomekeke kwindawo eya kubonakaliswa kuyo kunye neendaba eziya kuzitywina.Izinto eziqhelekileyo ziquka i-nitrile rubber (NBR), i-fluorocarbon (iViton), i-silicone, i-EPDM, kunye ne-neoprene.Imathiriyeli nganye ineempawu zayo ezizodwa, njengokunganyangeki kwiqondo lobushushu, imichiza kunye nokuqhawuka.

3.2.Ubungakanani kunye neDimension

Amakhonkco e-O afumaneka ngobukhulu obahlukeneyo kunye nemilinganiselo, evumela ukuba ilingane i-grooves kunye neendawo zokukhwelana.Ubungakanani bunqunywe yi-diameter yangaphakathi (ID), i-diameter yangaphandle (OD), kunye ne-cross-sectional thickness.Umlinganiselo ochanekileyo kunye nokulinganisa okufanelekileyo kubalulekile ekutywinweni okusebenzayo.

3.3.Imilo yoMnqamlezo weCandelo

Ngelixa i-cross-section ejikelezayo ixhaphake kakhulu, i-O-rings nayo inokuza kwiimilo ezahlukeneyo, njenge-square, i-rectangular, kunye ne-X-shaped profiles.Ukukhethwa kobume obunqamlekileyo kuxhomekeke kwiimfuno ezithile zesicelo, kubandakanywa ukunyanzeliswa koxinzelelo kunye nokuhambelana neendawo zokukhwelana.

Usetyenziso lwe-O-rings

I-O-rings ifumana ukusetyenziswa okubanzi kuluhlu olubanzi lwezicelo kuwo wonke amashishini.Eminye imizekelo eqhelekileyo ibandakanya iisistim zehydraulic, iinkqubo zomoya, iinjini zeemoto, iimpompo, iivalvu, uqhagamshelo lwemibhobho yamanzi, kunye nezixhobo zonyango.Ukuguquguquka kwabo, ukuthembeka, kunye nokusebenza kakuhle kweendleko kubenza babe lukhetho oludumileyo lwezisombululo zokutywinwa.

Ukubaluleka koFakelo olululo

Ufakelo olululo lubalulekile ukuqinisekisa ukusebenza kwe-O-ring ngeyona ndlela.Izinto ezinjengoyilo oluchanekileyo lwegroove, ukulungiswa komphezulu, ukuthambisa, kunye noxinzelelo zidlala indima ebalulekileyo ekuphumezeni itywina elisebenzayo.Ukuqwalaselwa ngokucophelela kwiinkqubo zokufakela kunokuthintela ukuvuza, ukungaphumeleli kwangaphambi kwexesha, kunye nexesha lokunciphisa inkqubo.

Izinto ezichaphazela ukusebenza kwe-O-ring

Izinto ezininzi zinokuchaphazela ukusebenza kwe-O-rings kwizicelo zehlabathi zangempela.Kubalulekile ukuqwalasela le miba ngexesha loyilo kunye nenkqubo yokukhetha:

6.1.Ubushushu

Ubushushu obugqithisileyo bunokuchaphazela iipropati zezinto ze-O-ring, ezikhokelela ekubeni ukuqina okanye ukuthambisa.Kubalulekile ukukhetha imathiriyeli enokumelana noluhlu lobushushu obucetyiweyo ukunqanda ukuhla nokulahleka kokusebenza kokutywinwa.

6.2.Uxinzelelo

Uxinzelelo olwenziwa kwi-O-ring luchaphazela amandla ayo okutywinwa.Izicelo zoxinzelelo oluphezulu zifuna izinto ezinokumelana noxinzelelo oluhle kakhulu kunye namandla aneleyo okugcina isitywina esithembekileyo phantsi komthwalo.

6.3.Ukuhambelana kweMichiza

Ulwelo oluthile okanye iigesi zinokuba ndlongondlongo kwizinto ze-O-ring, ezibangela ukudumba kweekhemikhali, ukuthotywa, okanye ukulahleka kwe-elasticity.Ukuqonda ukuhambelana kweekhemikhali phakathi kwezinto ze-O-ring kunye neendaba eziza kudibana nazo kubalulekile ukuqinisekisa ukusebenza okuhlala ixesha elide.

Iindlela eziqhelekileyo zokungaphumeleli kwe-O-ring

Nangona ukuthembeka kwabo, i-O-rings inokufumana ukungaphumeleli phantsi kweemeko ezithile.Ukuqonda ezi ndlela zokusilela kunokunceda ekuchongeni imiba enokubakho kunye nokuphumeza amanyathelo okuthintela:

7.1.Extrusion

I-Extrusion yenzeke xa i-O-ring material inyanzeliswa kwi-gap yokucoca phakathi kweendawo zokukhwelana, okubangela umonakalo ongunaphakade.Oku kunokubangelwa kukukhutshwa okugqithisileyo, uxinzelelo oluphezulu, okanye ubunzima obungonelanga bezinto eziphathekayo.

7.2.Iseti yoxinzelelo

Iseti yokucinezela ibhekisa ekungakwazini kwe-O-ring ukuphinda imilo yayo yoqobo emva kokuba icinezelwe ixesha elide.Inokuthi yenzeke ngenxa yezinto ezifana nokushisa okuphezulu, ukukhethwa kwezinto ezingafanelekanga, okanye ukunyanzeliswa okunganeleyo ngexesha lofakelo.

7.3.Uhlaselo lweMichiza

Uhlaselo lwekhemikhali lwenzeka xa i-O-ring imathiriyeli isabela kunye neendaba ukuba itywinwe, okukhokelela ekudumbeni, ukuqina, okanye ukuthotywa.Kubalulekile ukukhetha imathiriyeli ehambelana neekhemikhali kunye nendawo ecetywayo yokusetyenziswa.

Iingcebiso ze-O-ring Maintenance

Ukuqinisekisa ubude obude kunye nokuthembeka kwe-O-ring seal, iinkqubo zokugcinwa rhoqo kufuneka zilandelwe:

Hlola i-O-ring ngeempawu zokuguga, ukonakala, okanye ukuwohloka.

Tshintsha ii-O-rings njengenxalenye yeeshedyuli zokhuseleko lolondolozo.

Coca imiphezulu yokukhwelana phambi kokuba uyifake kwakhona ukunqanda ukosuleleka.

Faka i-lubrication efanelekileyo ukunceda ukufakela kunye nokunciphisa ukukhuhlana.

Gcina i-O-rings kwindawo epholileyo, eyomileyo, kude nelanga okanye imichiza.

Ukukhetha uMboneleli we-O-ring oLungileyo

Ukukhetha umthengisi we-O-ring othembekileyo nothembekileyo kubalulekile ekufumaneni iimveliso ezikumgangatho ophezulu ezihlangabezana neemfuno zakho ezithile.Qwalasela izinto ezinjengomgangatho wemveliso, iziqinisekiso zemathiriyeli, ubuchule boshishino, kunye nenkxaso yabathengi xa ukhetha umthengisi.

Ukuqukumbela

I-O-rings zizinto eziyimfuneko zokutywinwa ezibonelela ngezisombululo ezisebenzayo nezisebenzayo kuwo wonke amashishini ahlukeneyo.Ukuqonda iindidi zabo, usetyenziso, ingqwalasela yofakelo, kunye nezenzo zogcino kubalulekile ekufezekiseni ukusebenza kakuhle kunye nokuthintela ukungaphumeleli kweendleko.Ngokunikela ingqalelo kwizinto ezinjengokukhethwa kwezinto, ubungakanani, iimeko zokusingqongileyo, kunye nofakelo olufanelekileyo, ii-O-rings zinokuzalisekisa ngokuthembekileyo imisebenzi yazo yokutywinwa.

Ii-FAQs

Q1.Ndiwubona njani ubungakanani obufanelekileyo be-O-ring yesicelo sam?

Ukumisela ubungakanani obufanelekileyo be-O-ring, kufuneka ulinganise i-diameter yangaphakathi (ID), i-diameter yangaphandle (OD), kunye ne-cross-sectional thickness.Sebenzisa ii-calipers okanye izixhobo zokulinganisa ezenzelwe ngokukodwa ii-O-rings ukufumana imilinganiselo echanekileyo.Ukongeza, jonga iitshathi zesayizi ye-O-ring okanye ufikelele kumthengisi ukuze ufumane isikhokelo.

Q2.Ndingayisebenzisa kwakhona i-O-ring?

Ngokuqhelekileyo akukhuthazwa ukuba uphinde usebenzise i-O-rings.Nokuba zibonakala zingonakali, ii-O-rings zinokuphulukana ne-elasticity kunye neempawu zokutywinwa emva kokuba zixinzelelwe kwaye ziphantsi kokutshintsha kweqondo lokushisa.Kungcono ukutshintsha i-O-rings ngexesha lokugcinwa okanye xa udibanisa amacandelo.

Q3.Kufuneka ndenze ntoni ukuba i-O-ring ayiphumelelanga phambi kwexesha?

Ukuba i-O-ring ayiphumelelanga kwangaphambi kwexesha, kubalulekile ukuchonga unobangela wokungaphumeleli.Jonga izinto ezifana nokuhambelana kwezinto, iinkqubo zofakelo, iimeko zokusingqongileyo, kunye neeparamitha zenkqubo.Ukwenza uhlengahlengiso oluyimfuneko, njengokukhetha izinto ezahlukeneyo okanye ukuphucula iindlela zokufakela, kunokunceda ukuthintela ukungaphumeleli kwixesha elizayo.

Q4.Ndingasebenzisa nasiphi na isithambiso nge-O-rings?

Hayi, ayizizo zonke izithambiso ezifanelekileyo ukuba zisetyenziswe nge-O-rings.Kubalulekile ukukhetha i-lubricant ehambelana ne-O-ring material kunye nokusingqongileyo kwesicelo.I-Silicone-based lubricants isetyenziswa ngokuqhelekileyo, kodwa kungcono ukudibana nomenzi we-O-ring okanye umthengisi ngeengcebiso ezithile zokuthambisa.

Q5.I-O-rings ihlala ixesha elingakanani?

Ubomi be-O-rings bunokwahluka ngokuxhomekeke kwizinto ezifana nesicelo, iimeko zokusebenza, kunye nomgangatho wezinto eziphathekayo.Ngokufakela okufanelekileyo, ukugcinwa, kunye nokukhethwa kwezinto eziphathekayo, i-O-rings inokubonelela ngokutywinwa okuthembekileyo ixesha elide, ukusuka kwiinyanga ukuya kwiminyaka emininzi.