Taw qhia rau O-rings

O-ring yog dab tsi?

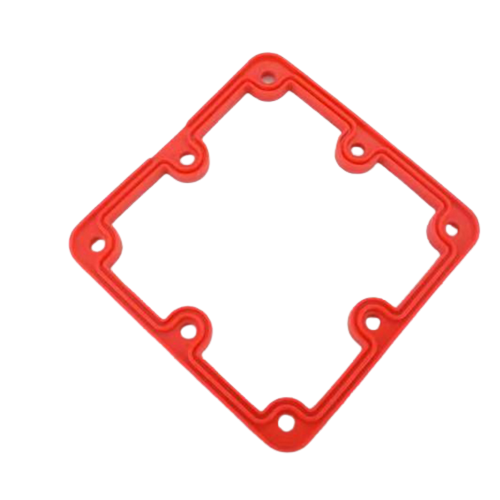

Lub nplhaib O-ring yog lub voj voog sib khi ua los ntawm cov khoom siv elastomer, feem ntau yog roj hmab lossis silicone.Nws tsim zoo ib yam li lub voj voos zoo li lub voj voog nrog ib puag ncig hla ntu.Lub O-ring lub luag haujlwm tseem ceeb yog tsim kom muaj kev sib khi ntawm ob qhov chaw sib txuas, tiv thaiv kev nkag mus ntawm cov kua lossis roj.Nws ua tiav qhov no los ntawm kev compressed ntawm qhov chaw, tsim kom muaj kev nruj thiab txhim khu kev qha.

Hom O-rings

Thaum xaiv O-ring rau ib daim ntawv thov tshwj xeeb, ntau yam yuav tsum tau xav txog.Cia peb tshawb txog cov ntsiab lus tseem ceeb los tsom mus rau:

3.1.Kev xaiv khoom

Kev xaiv ntawm cov khoom siv O-ring nyob ntawm ib puag ncig nws yuav raug nthuav tawm thiab cov xov xwm nws yuav kaw.Cov ntaub ntawv muaj xws li nitrile roj hmab (NBR), fluorocarbon (Viton), silicone, EPDM, thiab neoprene.Txhua yam khoom muaj nws cov khoom tshwj xeeb, xws li tiv taus kub, tshuaj, thiab puas.

3.2.Loj thiab Dimension

O-rings muaj nyob rau hauv ntau qhov ntau thiab tsawg, tso cai rau lawv kom haum rau qhov sib txawv grooves thiab mating nto.Qhov luaj li cas yog txiav txim los ntawm lub puab txoj kab uas hla (ID), sab nraud txoj kab uas hla (OD), thiab cross-sectional thickness.Kev ntsuas qhov tseeb thiab qhov loj me yog qhov tseem ceeb rau kev sib khi zoo.

3.3.Hla-Sectional Shape

Thaum lub voj voog hla ntu yog feem ntau, O-rings kuj tuaj yeem tuaj yeem sib txawv, xws li square, rectangular, thiab X-shaped profiles.Qhov kev xaiv ntawm cov duab hla-sectional nyob ntawm qhov kev thov tshwj xeeb, suav nrog kev ua haujlwm siab thiab kev sib raug zoo nrog cov mating nto.

Kev siv ntawm O-rings

O-rings pom kev siv dav hauv ntau hom kev siv thoob plaws kev lag luam.Qee qhov piv txwv xws li hydraulic systems, pneumatic systems, automotive engines, twj, li qub, kav dej txuas, thiab cov khoom siv kho mob.Lawv versatility, kev cia siab, thiab nqi-zoo ua rau lawv ib tug nrov kev xaiv rau sealing kev daws teeb meem.

Qhov tseem ceeb ntawm kev txhim kho kom raug

Kev txhim kho kom zoo yog qhov tseem ceeb los xyuas kom pom O-ring kev ua tau zoo.Cov yam ntxwv xws li kev tsim zawj kom raug, kev npaj saum npoo, lubrication, thiab compression ua lub luag haujlwm tseem ceeb hauv kev ua tiav kev foob zoo.Ua tib zoo saib xyuas cov txheej txheem kev teeb tsa tuaj yeem tiv thaiv kev xau, kev ua tsis tiav ntxov, thiab lub sijhawm poob haujlwm.

Cov yam ntxwv cuam tshuam rau kev ua haujlwm ntawm O-ring

Ntau yam tuaj yeem cuam tshuam kev ua haujlwm ntawm O-rings hauv kev siv tiag tiag hauv ntiaj teb.Nws yog ib qho tseem ceeb uas yuav tau xav txog cov xwm txheej no thaum lub sij hawm tsim thiab xaiv cov txheej txheem:

6.1.Kub

Qhov kub thiab txias tuaj yeem cuam tshuam rau O-ring cov khoom, ua rau tawv tawv lossis muag muag.Nws yog ib qho tseem ceeb heev uas yuav tau xaiv cov khoom siv uas tuaj yeem tiv taus qhov kub thiab txias kom tsis txhob muaj kev puas tsuaj thiab poob ntawm kev sib khi zoo.

6.2.Siab

Lub siab ua haujlwm ntawm O-ring cuam tshuam nws lub peev xwm sealing.High-pressure daim ntaub ntawv yuav tsum tau cov ntaub ntawv uas zoo heev compression teeb kuj thiab txaus lub zog los tuav ib tug txhim khu kev qha foob nyob rau hauv load.

6.3.Tshuaj Compatibility

Qee cov kua dej lossis cov pa roj tuaj yeem ua rau cov ntaub ntawv O-ring tuaj yeem ua rau muaj tshuaj lom neeg o, degradation, lossis poob elasticity.Nkag siab txog cov tshuaj sib raug zoo ntawm cov khoom siv O-ring thiab cov xov xwm uas nws yuav nkag mus rau hauv kev sib cuag nrog nws yog qhov tseem ceeb los xyuas kom meej kev ua haujlwm ntev.

Hom O-ring tsis ua haujlwm

Txawm hais tias lawv muaj kev ntseeg siab, O-rings tuaj yeem ua tsis tau raws li qee yam xwm txheej.Kev nkag siab txog cov hom kev ua tsis tiav no tuaj yeem pab txheeb xyuas cov teeb meem muaj peev xwm thiab siv cov kev tiv thaiv:

7.1.Extrusion

Extrusion tshwm sim thaum cov khoom siv O-ring raug yuam mus rau hauv qhov sib txawv ntawm qhov sib tov, ua rau muaj kev puas tsuaj mus tas li.Qhov no tuaj yeem tshwm sim los ntawm kev tshem tawm ntau dhau, kev kub ntxhov siab, lossis cov khoom siv tsis txaus.

7.2.Compression Teeb

Cov txheej txheem compression yog hais txog O-ring qhov tsis muaj peev xwm rov qab tau nws cov duab qub tom qab raug compressed rau lub sijhawm ntev.Nws tuaj yeem tshwm sim vim muaj qhov kub thiab txias, xaiv cov khoom siv tsis txaus, lossis compression tsis txaus thaum lub sijhawm teeb tsa.

7.3.Tshuaj tua kab mob

Tshuaj tua kab mob tshwm sim thaum cov khoom siv O-ring reacts nrog cov xov xwm nws yog sealing, ua rau o, hardening, los yog degradation.Nws yog ib qho tseem ceeb heev uas yuav tau xaiv cov khoom siv uas muaj tshuaj lom neeg nrog rau qhov chaw ua haujlwm.

Cov lus qhia rau O-ring Maintenance

Txhawm rau ua kom lub neej ntev thiab kev ntseeg siab ntawm O-ring seals, kev saib xyuas tsis tu ncua yuav tsum ua raws li:

Tshawb xyuas O-rings rau cov cim qhia ntawm kev hnav, kev puas tsuaj, lossis kev puas tsuaj.

Hloov O-rings ua ib feem ntawm kev tiv thaiv kev tiv thaiv.

Ntxuav mating nto ua ntej reinstallation kom tsis txhob muaj kab mob.

Siv cov lubrication tsim nyog los pab hauv kev teeb tsa thiab txo kev sib txhuam.

Khaws O-rings nyob rau hauv qhov chaw txias, qhuav kom deb ntawm tshav ntuj ncaj qha lossis tshuaj lom neeg.

Xaiv txoj cai O-ring Supplier

Xaiv lub npe nrov thiab txhim khu kev qha O-ring tsum yog qhov tseem ceeb kom tau txais cov khoom zoo uas ua tau raws li koj cov kev xav tau tshwj xeeb.Xav txog yam xws li cov khoom zoo, cov ntaub ntawv pov thawj, kev tshaj lij kev lag luam, thiab kev txhawb nqa cov neeg siv khoom thaum xaiv tus neeg muag khoom.

Xaus

O-rings yog qhov tseem ceeb ntawm cov khoom sib khi uas muab cov kev daws teeb meem zoo thiab muaj txiaj ntsig thoob plaws ntau yam kev lag luam.Kev nkag siab txog lawv hom, kev siv, kev xav txog kev teeb tsa, thiab kev saib xyuas yog qhov tseem ceeb rau kev ua tiav kev ua haujlwm zoo thiab tiv thaiv kev ua tsis tau zoo.Los ntawm kev xyuam xim rau yam xws li kev xaiv cov khoom, qhov loj me, ib puag ncig, thiab kev teeb tsa kom zoo, O-rings tuaj yeem ua tiav lawv txoj haujlwm sib khi.

FAQs

Q1.Kuv yuav txiav txim siab qhov loj npaum li cas O-ring rau kuv daim ntawv thov?

Txhawm rau txiav txim siab qhov loj ntawm O-ntiv nplhaib, koj yuav tsum ntsuas lub taub sab hauv (ID), sab nraud (OD), thiab hla ntu tuab.Siv cov calipers lossis ntsuas cov cuab yeej tshwj xeeb tsim rau O-rings kom tau txais kev ntsuas raug.Tsis tas li ntawd, sab laj O-ring loj kab kos lossis ncav cuag tus neeg muag khoom rau kev taw qhia.

Q2.Kuv puas tuaj yeem rov siv O-ring?

Nws feem ntau tsis pom zoo kom rov siv O-rings.Txawm hais tias lawv zoo li tsis muaj kev puas tsuaj, O-rings tuaj yeem poob lawv cov elasticity thiab sealing zog tom qab compressed thiab raug kub hloov pauv.Nws yog qhov zoo tshaj los hloov O-rings thaum lub sij hawm tu los yog thaum disassembling Cheebtsam.

Q3.Kuv yuav ua li cas yog tias O-ring ua tsis tiav?

Yog tias O-ring ua tsis tiav ntxov, nws yog qhov tseem ceeb los txheeb xyuas qhov laj thawj ntawm kev ua tsis tiav.Tshawb xyuas yam xws li cov khoom siv sib xws, cov txheej txheem kev teeb tsa, ib puag ncig, thiab cov txheej txheem tsis ua haujlwm.Kev hloov kho tsim nyog, xws li xaiv cov khoom sib txawv lossis txhim kho cov txheej txheem kev teeb tsa, tuaj yeem pab tiv thaiv kev ua tsis tiav yav tom ntej.

Q4.Kuv puas tuaj yeem siv cov roj nplua nyeem nrog O-rings?

Tsis yog, tsis yog txhua lub roj nplua nyeem tsim nyog siv nrog O-rings.Nws yog ib qho tseem ceeb uas yuav tau xaiv cov roj nplua nyeem uas sib haum nrog cov khoom siv O-ring thiab ib puag ncig kev thov.Silicone-based lubricants feem ntau yog siv, tab sis nws yog qhov zoo tshaj plaws los sab laj O-ring cov chaw tsim khoom lossis cov chaw muag khoom rau cov lus pom zoo tshwj xeeb.

Q5.O-rings feem ntau kav ntev npaum li cas?

Lub neej ntev ntawm O-rings tuaj yeem sib txawv nyob ntawm seb yam xws li daim ntawv thov, kev ua haujlwm, thiab cov khoom siv zoo.Nrog rau kev txhim kho kom zoo, kev saib xyuas, thiab xaiv cov khoom siv, O-rings tuaj yeem muab kev sib khi ruaj khov rau lub sijhawm ntev, txij li lub hlis mus rau ntau xyoo.